PEFC certification increases our recognition and reliability

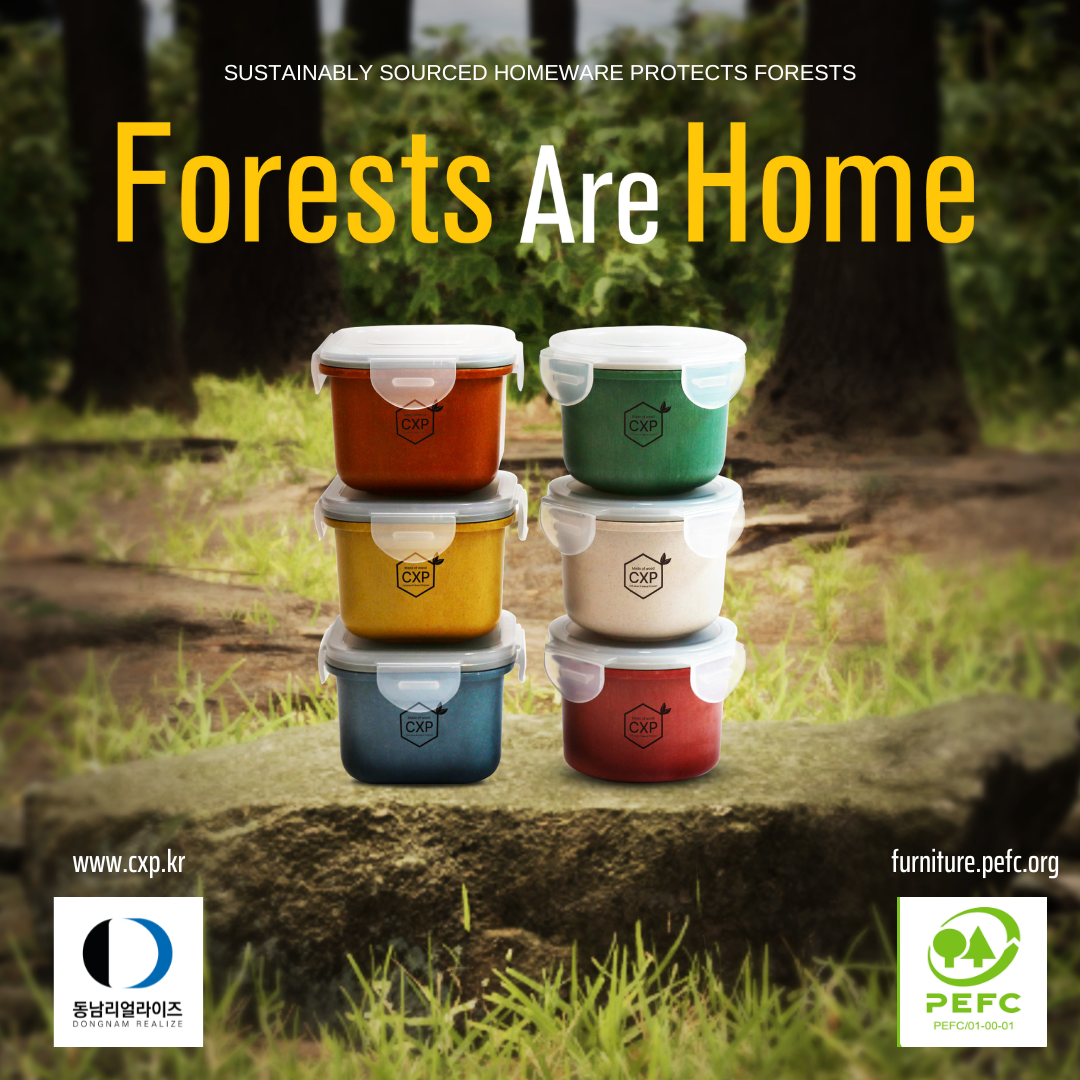

Korean company Dongnam Realize found a sustainable alternative to plastic. Made from PEFC-certified wood, CXP can replace the plastic products we use in our daily lives.

PEFC certification increases our recognition and reliability

26 October 2022 Certification on the ground

After its invention in the 20th century, plastic was seen as a miracle material. Today, we know about the various health and environmental risks it brings.

Not only does plastic contribute to air pollution by emitting CO2, microplastics are also increasingly accumulating in the human body through the food chain, causing serious health issues.

Korean company Dongnam Realize found a sustainable alternative in CXP, a new kind of thermosoftening wood made from PEFC-certified wood. Thanks to its plastic-like properties, CXP can replace the plastic products we use in our daily lives.

We spoke to Seunghoon Lim, Chief Technology Officer at Dongnam Realize, who told us more about the material and its potential to make the future more sustainable.

Can you give us a brief introduction to your company and its position in the market?

Dongnam Realize manufactures CXP, a thermoplastic, non-toxic wood material using forestry by-products.

CXP wood products have properties that can replace general-purpose plastics. CXP is an eco-friendly, non-toxic material, not based on plastic resins, which makes it unique. We are currently doing business with many companies that are looking for eco-friendly alternatives.

In the context of forest-based product sourcing, what is your company’s goal?

Various forestry by-products are generated around the world: six million tons per year in Korea alone. Our goal is to promote sustainable forest management and reduce plastic waste and carbon emissions by using forestry by-products and thinned logs.

Adding value to these by-products will be an incentive for forestry workers to practice sustainable forest management. Through this, we hope to expand the area of sustainably managed forests.

Tell us a bit about yourself. What is your background? What are your main responsibilities within the company?

I became aware of the potential of using domestic wood while conducting various recreational forest design projects with the Korea Forest Service.

We started with the development of CXP for decks that can be used as a building material. CXP wood for injection processing was commercialized for the first time last year.

Part of my role as technology director is Research and Development and Technical Support to enable the production of various products using CXP.

What led you to choose PEFC certification?

We first heard about PEFC and its member for Korea, KFCC, at the international plastic and rubber industry exhibition KOPLAS, and obtained PEFC certification this January.

PEFC is comprised of various national systems around the world, and strives to unite them through a single value, while respecting the characteristics and certification methods of the local forests.

We consider PEFC’s approach as very decent. The fact that it is a reliable system operated by a domestic public organization, the Korea Forestry Promotion institute, is one of our reasons for choosing PEFC.

How has PEFC certification benefited your company and helped achieve your goals?

PEFC certification helped us expand the business by allowing customers to clearly recognize the category of CXP wood as “wood”.

When introducing the material to consumers and producers who will use CXP wood, PEFC certification increases our recognition and reliability. This is a very high value that is difficult to quantify numerically.

What does it mean for you personally to work for a company that takes its responsibility for forests seriously?

We feel deeply rewarded because we work for a company that works for the environment from the starting line, not just a company that advocates eco-friendliness.

In your opinion, what role will sustainability and certification play in your sector in the future?

Sustainability and forest certification are in line with the fundamentals of CXP wood’s identity. Dongnam Realize will continue to make efforts to ensure that the use of CXP wood and products can help develop forestry and protect the environment.

The raw material for CPX wood comes from PEFC-certified forests all over South Korea. It mainly consists of dumped twigs and small pieces of wood. It's even more meaningful because it creates new value by giving a use to supposedly useless things.